Spilker Converting Solutions

In case of high product requirements, demanding materials and many processing steps which are combined inline, it is important that a converting machine can be used flexibly.

In order to cover these manifold requirements with only one machine, an adaptable machine concept is necessary. Beside the possibility to combine different cutting and laminating processes as required, also the decisive factors in the production process must be precisely controllable. Details such as the angle, in which a stamping grid is removed or material is fed, and the correct web tension are factors which often decide if and how successful an order can be produced.

Materials with strong sticking, flowing adhesives, plastics, elastomers and acrylate foams, but also thick and abrasive materials have their own specifics with regard to processing.

This is where the S-CON Smartline steps in. Designed for the rotary processing of the most differing materials, the converting machines offer considerable production possibilities in order to put into practice also challenging and complex processes.

S-CONtrol machine control

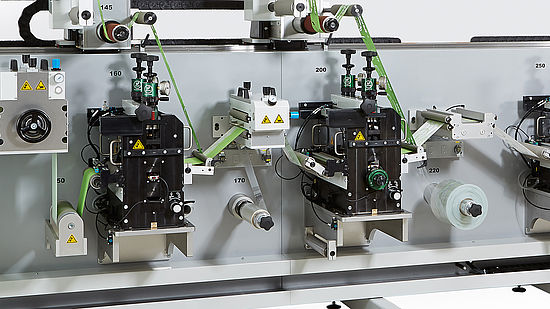

Thanks to the open machine concept the individual components are easily accessible and it ensures the best possible insight in the manufacturing process. Due to the possibility of free positioning and shifting of the moveable top winders over the entire length of the S-CON Smartline, material can be fed or removed at different positions. The angle can be continuously adjusted and the winders can be used as rewinders or unwinders. Pressure rollers guarantee a neat winding of stamping grids.

The control is made over an operating panel which can also be moved over the entire length of the machine. With the user surface S-CONtrol the production process can be influenced with numerous parameters and optimally adjusted to the material requirements. Once the correct adjustments for an order have been found, these can be recorded and called up again in case of a repeat production. This ensures a reliable reproducibility.

Deviations are detected and compensated

Modern sensor technology detects deviations and compensates these via the machine control. The pulling forces for each servo motor can be exactly adjusted which ensures a precise adaptation of the web tension to the respective tasks.

The entire converting machine is equipped with multiple devices to simplify operation and for an exact control. With the Spilker MovingBridge the tool change in the cutting units can be realized easily and comfortably. The tool can be reached and exchanged with only a few handles. Via the machine control the cutting pressure can be switched on and off with the aid of the Spilker PowerBridge in an absolutely reproducible manner. This is helpful during machine setup and minimizes the wear of the tools.

With Spilker PowerCheck which is built in every cutting unit the cutting pressure can be precisely read off and adjusted. The result are longer lifetimes and better cutting results. Additionally the distance between the cutting tool and the counter pressure cylinder can be set in the μ-range with the MicroGap – the adjustable counter pressure cylinder by Spilker. Beside the exact control und supervision of the handling process these devices from Spilker facilitate the compliance of minimum tolerances and ensure precise cuttings.

If you also require support with a project, you can find the right contact person here:

Contact persons