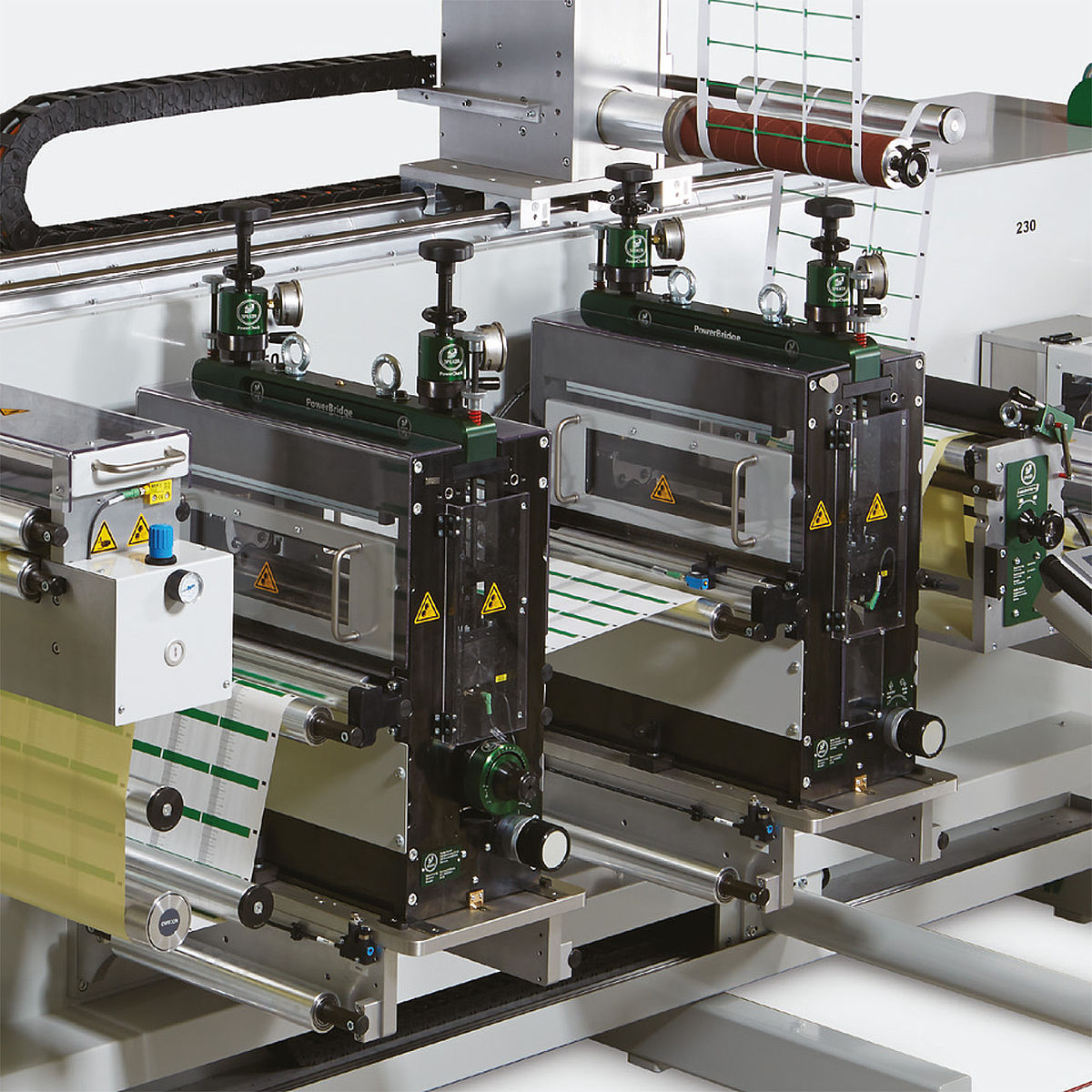

S-CON Smartline

Open new markets with our flexibly configurable rotary machines that are 100% tailored to your needs.

Innovative solutions for various applications

With the S-CON Smartline complex processing processes can be implemented in a space-saving and individual way, since the individual components can be freely positioned on the rear wall during conception. This open machine concept ensures good accessibility and allows optimal insight into the processing steps for the process monitoring.

Possible configurable processes:

- Production roll-to-roll and roll-to-sheet or single piece

- Rotary cutting (fully rotary, male/female, semi-rotary)

- Slitting / Cross cutting

- Dispensing, coating / laminating, embossing

- Web inspection, if necessary with removal of defective parts

- Delivery belt, vacuum delivery belt, stacking unit

- Insetter + register control

- Repeat enlargement, Multilayer

- Printing of the material web (flexographic or digital printing)

Optional additional equipment:

- Movable winding / unwinding towers

- Vacuum pull station for sensitive materials

- Decurling unit for smoothening the material

- Aspiration for punching waste

- Tandem and turret winder

- Friction shafts

Optional extensions:

- Antistatic equipment

- Corona unit, UV-drying

- Laser cutting

- Ultrasonic welding

Technical data

| Web width | 150 - 350 mm* |

| Speed mech. max. | 150 m/min |

| Roll diameter up to | 1200 mm |

| Power supply | 400 V 50/60 Hz /N/PE |

| Pneumatic supply | 6 - 8 bar |

* other web widths on request

Your advantages

- Complex handling processes can be implemented in a space-saving and individual way

- Single-sided mounting enables optimal accessibility of the components

- High flexibility due to numerous production possibilities in one machine

- Very short setup times and material savings when setting up thanks to user-friendly equipment and additional features

- Intuitive interface

- Movable control panel allows process monitoring with simultaneous process control